Digital twin technology is a virtual replica of physical systems, capturing real-time data to mirror and optimize performance. This technology is transforming industries by providing detailed insights and improving efficiencies.

Digital twins allow businesses to simulate scenarios, predict outcomes, and make better decisions. They are quickly becoming essential for digital transformation, unlocking the value of data across enterprises.

Digital twins integrate IoT, AI, and analytics to help organizations visualize operations, anticipate issues, and streamline processes.

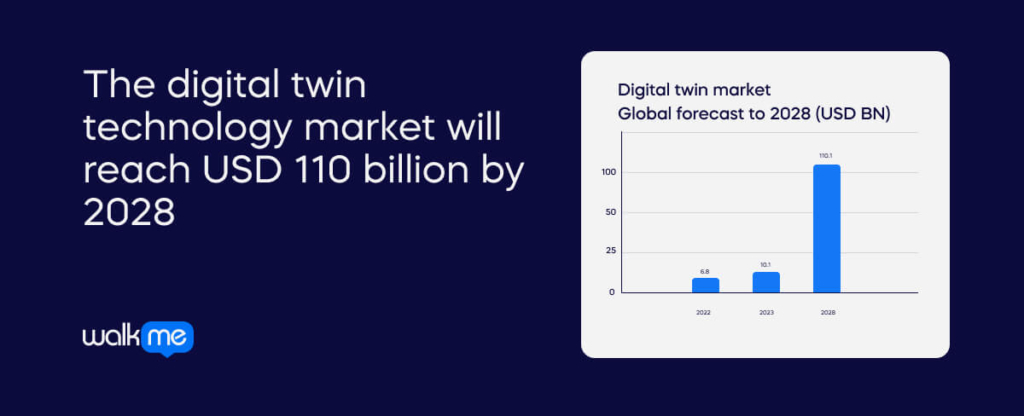

The digital twin technology market will reach USD 110 billion by 2028. Now is the time to invest in competing on a level playing field and ensure your enterprise’s sustainability with current digital tools.

This article explores the definition, types, and examples of digital twin technology, highlighting its role in enhancing business innovation and competitiveness.

What is digital twin technology?

Digital twin technology uses a virtual counterpart of a physical item, reflecting its lifecycle using real-time sensor data. It can mimic anything from individual factory machinery to systems like wind turbines or entire cities.

This technology facilitates asset performance tracking, fault identification, and smarter decision-making about maintenance and lifecycle. It allows new design choices to improve infrastructure in a virtual environment for cost optimization, saving money by allowing design to take place on a large scale before construction.

Why is digital twin technology important?

Digital twins are virtual replicas connected to real-world data sources, allowing them to update in real-time to mirror their physical counterparts. They incorporate a layer of behavioral insights and data-driven visualizations.

Enhanced decision-making

Digital twins are powerful tools for making informed choices. By mirroring real-world systems and offering real-time data, they give us a deeper understanding of how things function. This translates to better decisions on everything from maintenance schedules to product design tweaks.

Optimized efficiency and productivity

Streamlining operations and maximizing output are key to success. Digital twins can help us achieve this by simulating scenarios and predicting potential issues before they arise. This allows us to refine processes, minimize downtime, and ensure resources are used effectively. The result? A significant boost in overall efficiency and productivity.

Accelerated innovation

Speeding up the innovation cycle is crucial in today’s fast-paced world. Digital twins provide a virtual environment where we can test new designs and features without physical prototypes. This enables us to experiment rapidly, iterate on ideas efficiently, and bring innovative products to market quickly.

Predictive maintenance

Imagine being able to prevent equipment failures before they happen. Digital twins offer this capability by continuously monitoring the health of their physical counterparts. This allows us to anticipate potential problems and schedule maintenance proactively. No more scrambling to fix unexpected breakdowns – predictive maintenance keeps things running smoothly and saves money in the long run.

Improved customer satisfaction

Delighting customers is paramount. Digital twins can be a valuable tool in achieving this goal. They allow us to personalize product experiences and provide exceptional customer service. Additionally, they enable us to gather valuable customer feedback to guide future product development. This translates to happier customers and a stronger competitive edge.

Digital twins promise to facilitate more flexible and robust operations. Top executives recognize this potential: 70 percent of technology executives in the C-suite at large corporations are already investigating and investing in digital twins.

What are the different types of digital twin technology?

There are four main types of digital twin technologies: component twins/ parts twins, asset twins, system/unit twins, and process twins. It is helpful to be aware of these types to ensure you invest in the right type for your needs.

Component twins/Parts twins

Component twins, also known as Parts twins, are the fundamental building blocks of a digital twin, representing the smallest functional unit. They are crucial because they provide detailed insights into the performance and health of individual components, which can be less significant but still vital for the overall system.

By monitoring these parts twins, organizations can predict potential failures, optimize maintenance schedules, and improve the overall efficiency and longevity of the system. This granular analysis level makes digital twins a powerful tool for modern industries.

Asset twins

Asset twins occur when two or more components interact, representing a larger functional unit within the digital twin framework. They allow for the study of component interactions and generate vast performance data.

This data can be analyzed and transformed into actionable insights, enhancing understanding system dynamics and interdependencies. The ability to scrutinize these interactions in a virtual environment is a significant advantage of digital twins. It enables predictive maintenance, system optimization, and improved decision-making, thereby playing a crucial role in the digital transformation of industries.

System or Unit twins

System or unit twins represent the next level of complexity in the digital twin hierarchy. They allow for observing how various assets integrate to create a fully operational system. These system twins offer transparency into the interplay of assets and can propose performance improvements.

The importance of system twins lies in their ability to model complex systems, providing a holistic view of operations. This comprehensive perspective identifies systemic inefficiencies and predicts system behavior under different conditions, facilitating strategic planning and informed decision-making. This action makes system twins an indispensable tool in the digital transformation journey of various industries.

Process twins

Process twins represent the highest level of magnification in the digital twin hierarchy, illustrating how multiple systems collaborate to form a complete production facility. They play a crucial role in assessing whether these systems synchronize for optimal efficiency or if delays in one system could impact others.

Process twins can assist in identifying the exact timing strategies that ultimately dictate operational effectiveness. By providing a macroscopic view of the entire process, they enable the detection of bottlenecks, synchronization issues, and inefficiencies at a process level.

This holistic understanding of the production process is vital for strategic planning, process optimization, and enhancing overall productivity, making process twins an essential component in the digital twin ecosystem.

What are some examples of digital twin technology?

It can take time to fully understand digital twins and how they may apply to your organization and industry. Here are three examples that allow you to see this technology in action. The first example covers how the Los Angeles Transportation services utilized digital twins.

Los Angeles transportation

Initially, it will simulate the dynamics and activities of micro-mobility solutions like the city’s shared bicycles and e-scooters network. Subsequently, the scope becomes broader, including ride-sharing services, carpooling, and emerging mobility solutions such as autonomous taxi drones.

The entirety of Shanghai

The Shanghai Urban Operations and Management Center has constructed a digital twin of the city. The city is home to 26 million people, which simulates 100,000 elements ranging from waste disposal and collection facilities to e-bike charging stations, road traffic, and the dimensions and locations of residential buildings.

The creator, 51World, employs data from satellites and drones to build this dynamic model. Among its various applications, it assists authorities in planning and responding to situations like the Covid-19 pandemic. Furthermore, it can simulate the impact of natural disasters like floods to aid emergency response planning.

NFL sports stadium

The Sofi Stadium in Los Angeles, the home ground for NFL teams the LA Rams and LA Chargers, boasts its digital twin. This digital twin replicates the stadium and the surrounding 300-acre Hollywood Park campus. Constructed concurrently with the physical stadium starting in 2020, this digital twin gathers real-time data from all operational areas of the park into a unified platform.

This platform can address queries from a wide range of users, from event organizers planning to utilize the space to maintenance and janitorial staff. Users interact with the digital twin through an “app store” model, enabling them to access applications tailored to their specific needs and functionalities.

What are some use cases for digital twin technologies?

You may wonder how to use digital twin technologies in different industries. See our use cases below for three popular ways to utilize digital twins in manufacturing, the automotive industry, and construction.

Construction

Digital twins allow construction companies to test different scenarios, such as design changes, weather disruptions, or security events. And all these can be done without disrupting the construction.

The virtual models provide a detailed look at how the asset is designed and performs in real-time. For example, it allows construction companies to see the lighting inside each hall and room, how much people can use the space, and more.

Digital twins can also pave the way for a more sustainable way of constructing buildings. You can read more about how digital twins can help with sustainable construction.

Digital Twin Example in Construction- Crossrail, London

Crossrail is a major infrastructure project in London. The engineers have used digital twins to visualize the finished product. They have also been able to monitor the project’s progress and spot potential issues.

They used the digital twins to simulate and optimize the construction process to make the workflow smoother. Furthermore, they also optimized their resource usage, avoiding any wastage

Manufacturing

The use of digital twins to boost manufacturing efficiency is becoming increasingly widespread. Manufacturers can expedite data evaluation, track performance trends over time, and fine-tune their operations by constructing a virtual model of an industrial process.

Digital twins are handy in overseeing production lines. Businesses can employ them to monitor key performance indicators such as temperature, pressure, and speed. They can also monitor environmental conditions and spot any irregularities in production, which could signal potential issues or defects.

Digital twins can offer predictive maintenance advice for machinery in the manufacturing sector. Consequently, they can pinpoint potential issues before they escalate into expensive breakdowns, thereby minimizing downtime and enhancing product reliability.

A prime example of digital twin usage in manufacturing is Rolls-Royce’s “IntelligentEngine” program. This program creates digital twins for each engine they manufacture, enabling them to collect data on more than a dozen parameters from onboard sensors. This real-time performance monitoring during flights allows for predictive maintenance and downtime reduction.

This program’s primary objective is to revolutionize how they deliver customer power. Digital twins achieve this goal by enhancing engine reliability and efficiency, improving the customer experience.

Automotive

Digital twins play a pivotal role in design, manufacturing, and aftermarket services in the automotive industry.

Engineers can experiment with various designs and choose the most efficient ones without needing a single physical prototype. The manufacturing process can experience streamlining, reducing downtime, and enhancing the production rate. Moreover, predictive maintenance can preemptively service vehicles before any issues arise.

Digital twins offer numerous benefits in the automotive industry. As the market transitions towards electric vehicles, their importance has become paramount.

You can also explore more resources to understand further the significance of digital twins in developing and maintaining electric vehicles.

An example of a digital twin application in the automotive industry is Volvo. Known for prioritizing passenger safety, Volvo employs digital twins to create virtual models for testing different materials and aerodynamics of new vehicle designs. This technology enables them to select the optimal design that enhances performance and promotes fuel efficiency.

How can a DAP support digital twin technology?

A digital adoption platform (DAP) can significantly enhance the utilization of digital twins. DAPs guide users through digital processes, improving their understanding and efficiency.

In the context of digital twins, a DAP can provide real-time assistance, helping users navigate complex digital twin interfaces, understand data visualizations, and execute tasks effectively. It achieves this using in-app guidance, allowing users to learn about digital twins while they work without disrupting their workflow.

These features can lead to better decision-making and improved operational efficiency. Furthermore, DAPs can facilitate the training process for new users, accelerating the adoption of digital twin technology across an organization. Thus, DAPs play a crucial role in maximizing the value derived from digital twins.

Explode your perspective with digital twins

Digital twins offer a transformative approach to understanding and optimizing complex systems. Creating virtual replicas of physical entities enables real-time monitoring, predictive analysis, and scenario testing.

This perspective explosion allows businesses to see large entities like countries or cities and focus on adjusting smaller areas, allowing them to make informed decisions, enhance operational efficiency, and innovate at an unprecedented pace.

As we move towards a more digitized future, the digital adoption and advancement of digital twin technology will undoubtedly play a pivotal role in shaping industries and economies worldwide.