What is supplier relationship management?

Supplier relationship management is about managing relationships with suppliers to get the most out of them. It is focused on creating mutually beneficial partnerships so that business goals can be achieved.

The aims of SRM are primarily to optimize supplier performance, handle risks and drive innovation throughout the supply chain. To develop effective SRM, it is important to build trust with suppliers, encourage open conversation and resolve conflicts quickly. SRM is crucial for organizations who want a reliable and efficient supply chain. Businesses can use SRM to drive innovation, reduce costs and improve their overall performance. Supply chain management has come under the spotlight in recent years. According to Gartner, 83% of practitioners surveyed say they are improving customer experience as part of organizational digital business strategy. AI is also rising to the forefront – for example, according to PwC, 70% of operations and supply chain officers surveyed revealed they have tested or rolled out generative AI in the workplace. It is therefore clear that supplier relationship management (SRM) needs to be managed more smartly as a component.

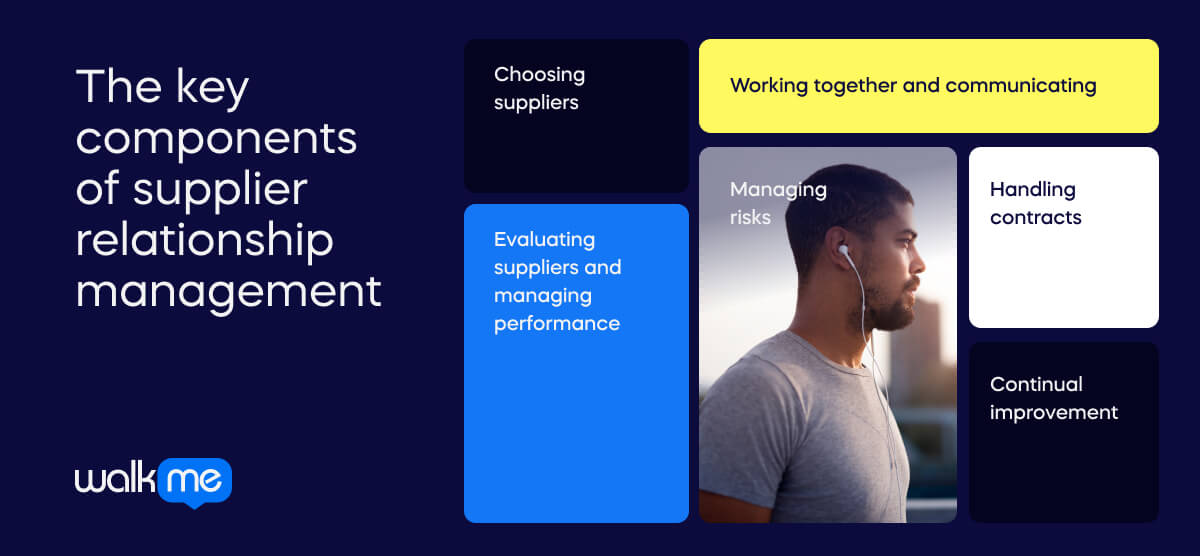

What are the key components of supplier relationship management?

Various activities comprise SRM. These include choosing a supplier, evaluating performance and continuously improving. With that in mind, here are the key components everyone involved in supplier relationship management should focus on:

Choosing suppliers

Choose the best suppliers based on quality, reliability, cost, and their fit with the company’s goals.

Evaluating suppliers and managing performance

Check how well suppliers are performing compared to standards, give feedback, and make plans to help them improve if necessary.

Working together and communicating

Talk openly with suppliers and work together to share information, generate new ideas, and improve things, such as developing products or improving processes.

Managing risks

Identify and deal with possible problems that could affect the relationship with suppliers, such as supply chain delays or product quality issues.

Handling contracts

Ensure that agreements with suppliers are followed correctly, including things like prices, conditions, and the level of service expected.

Continual improvement

Always look for ways to make the relationship with suppliers better, like finding ways to save money or improve the quality of products.

Supplier relationship management vs. supplier performance management

It can be easy to confuse supplier relationship management with supplier performance management. In essence:

- SRM is about fostering relationships and collaboration

- SPM is about assessing and managing the actual performance of suppliers

Here’s a more detailed breakdown:

| SRM | SPM | |

| Definition | Managing relationships with suppliers to make them valuable.Involves choosing and working with suppliers to reach business goals. | Focuses on checking and improving how well individual suppliers do.Watching their performance and making sure they meet expectations. |

| Focus | Mainly focuses on building strong relationships with suppliers.It’s about talking, working together, and making both sides happy. | Focuses on how suppliers perform.It’s about looking at their work and finding ways to make it better. |

| Techniques | Dividing suppliers into groupsHelping them get better Talking with them often | Setting goalsChecking how well suppliers do Giving feedback Making plans to improve |

| Goals | Build good relationships with supplierImprove processes Save money Come up with new ideas together | Make sure suppliers always provide good productsCheck they deliver on time Reduce risks Help suppliers get better Save money |

| Examples of use | Checking suppliersMaking deals Working together on new projects Sharing information Improving together | Watching when suppliers deliverChecking product quality Making sure suppliers follow agreements Giving feedback Fixing problems if needed |

Use cases for supplier relationship management

Supplier relationship management in business

Many different types of organizations use supplier relationship management. Here are some examples: Negotiating contracts

- A clothing brand talks to fabric suppliers to get good deals on materials.

- They want fair prices, good quality, and deliveries on time.

- By keeping good relationships with these suppliers, the brand gets what it needs to make clothes people want to buy.

Managing supply chain risks

- A tech company relies on suppliers for parts to make their products.

- They need to make sure they’re ready if something goes wrong, like a delay in getting parts or problems with quality.

- By working with different suppliers, checking things regularly, and having backup plans, the company can keep making its products even if there are problems.

Driving innovation

- A restaurant chain works with food suppliers to create new dishes for its menu.

- They share ideas and try out new ingredients to make food that people will love.

- By working closely with suppliers, the restaurant can stand out from others, attract more customers, and grow its business.

Advantages of supplier relationship management

Engaging in effective supplier relationship management has a number of benefits:

Better performance

Having good relationships with suppliers motivates them to do better work.

Cost savings

Being on good terms with suppliers can result in discounts and lower prices.

Flexibility

Changing plans quickly is made easier if companies and suppliers have a good relationship.

Competitive advantage

Companies can make the most of valuable insights and expertise from suppliers. This can give them an edge in the market.

Challenges of supplier relationship management

Supplier relationship management can come with its challenges:

Trust issues

It takes time to trust suppliers, and if they prove unreliable, it can damage business.

Conflict

Sometimes, conflict with suppliers can arise over issues like quality or delivery times.

Less choice

If there are fewer suppliers to pick from, it’s harder to get a good deal.

Changing requirements

As business grows and changes, different supplies may be needed. This can be hard to assess and manage.

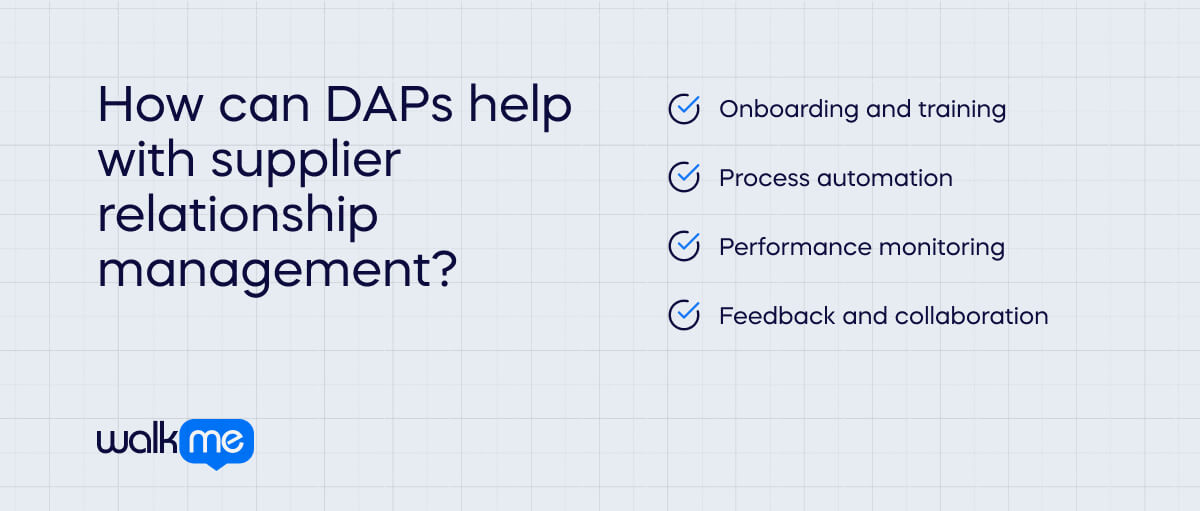

How can DAPs help with supplier relationship management?

A Digital Adoption Platform (DAP) can help with supplier relationship management (SRM) in the following ways: Onboarding and training A DAP teaches employees about SRM software with interactive guides. This helps them understand how to manage supplier relationships well.

| How can WalkMe help?Smart Walk-Thrus can help people learn new SRM software by giving them step-by-step guidance on the screen. They make learning easier by showing instructions as people work, so they can learn while doing. |

Process automation The software automates regular SRM tasks like adding suppliers and managing contracts. This saves time and reduces mistakes, letting employees focus on important parts of managing suppliers.

| How can WalkMe help?WalkMe Automation can move through processes without human input, autofill forms, automate scheduling and streamline SRM-related tasks by removing some of the steps required. |

Performance monitoring These platforms can track and analyze how employees are interacting with SRM software. The data can identify potential problems and suggest ways to improve processes.

| How can WalkMe help?WalkMe’s Workflow Analytics feature allows companies to make data-driven decisions and improve the performance of their SRM software. They can analyze workflows and ensure SRM processes are made smoother. |

Feedback and collaboration DAPs make it easy for employees to share ideas and suggest improvements to SRM software. This helps to improve digital adoption over time.

| How can WalkMe help?WalkMe Surveys allow feedback from users to be fed into Insights. They can be used to test knowledge, ask people what they need help with or find out what they think about a new feature. |

Success stories with supplier relationship management

WalkMe has helped numerous procurement teams with their supplier relationship management. Here’s how the DAP helped Smith + Nephew.

Smith + Nephew x WalkMe

When Smith + Nephew transitioned to SAP Ariba, the procurement team needed help with change management. Not only did they want to minimize support tickets, they also wanted to make sure employees followed policies and worked efficiently. The team deployed WalkMe features such as ShoutOuts to promote educational sessions, changes in procurement policy, information about new buying channels and more. They also built out support for the team, which enabled them to complete administrative tasks more efficiently. As a result, the organization has enjoyed a 70% decrease in errors and 2.5 hours per week saved in support hours. Plus, user satisfaction with SAP Ariba has now increased the company’s 80% target.

Future of supplier relationship management

Looking ahead, the future of smart SRM relies on digital adoption platforms. These tools use technology to make managing supplier relationships easier. With digital adoption platforms integrated with SRM software, companies can work faster, see what’s happening in real-time, and solve problems before they become big issues. For example, digital adoption platforms can complete tasks automatically and use data to predict problems. They help teams inside and outside the company work together better and find new ways to improve processes. In short, as technology keeps changing how we do business, using smart digital tools for SRM will help companies stay ahead, manage their suppliers well, and keep growing.